Out of Stock Detection.

"Out-of-stocks" account for over $129 billion in lost retail sales in North America (~4% of revenue), or $1.1 trillion globally. Not only that, but out-of-stocks can also actively drive customers into the arms of the competition: an IHL study found that 24% of Amazon’s revenue comes from customers who experienced an out-of-stock at a local retailer (source). The same study showed that a majority of the issues driving out-of-stocks were bad processes, people problems, and data/systems issues. That’s where Focal's operating system for inventory management comes in.

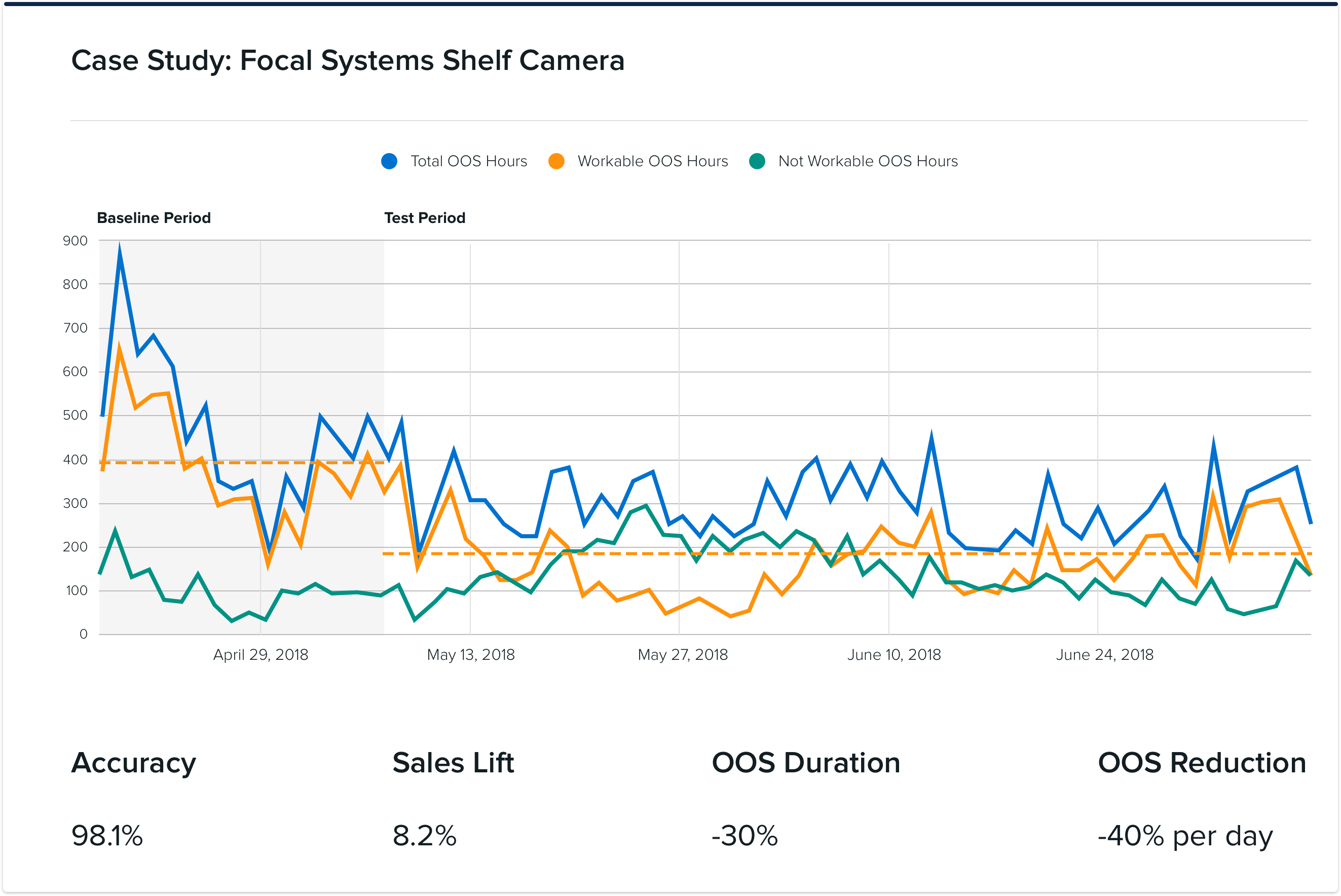

1. 30%+ increase in On-Shelf Availability and 8% increase in sales

Our system has been piloted in 10+ tier-1 retailers in 3 continents. We have consistently shown the efficacy of our system. With less labor, Focal Systems reduces your out of stock hours (the sum of all the time products are out) by over 30%. This results in an 8% increase in sales and happier customers.

Read our case study detailing how this was accomplished.

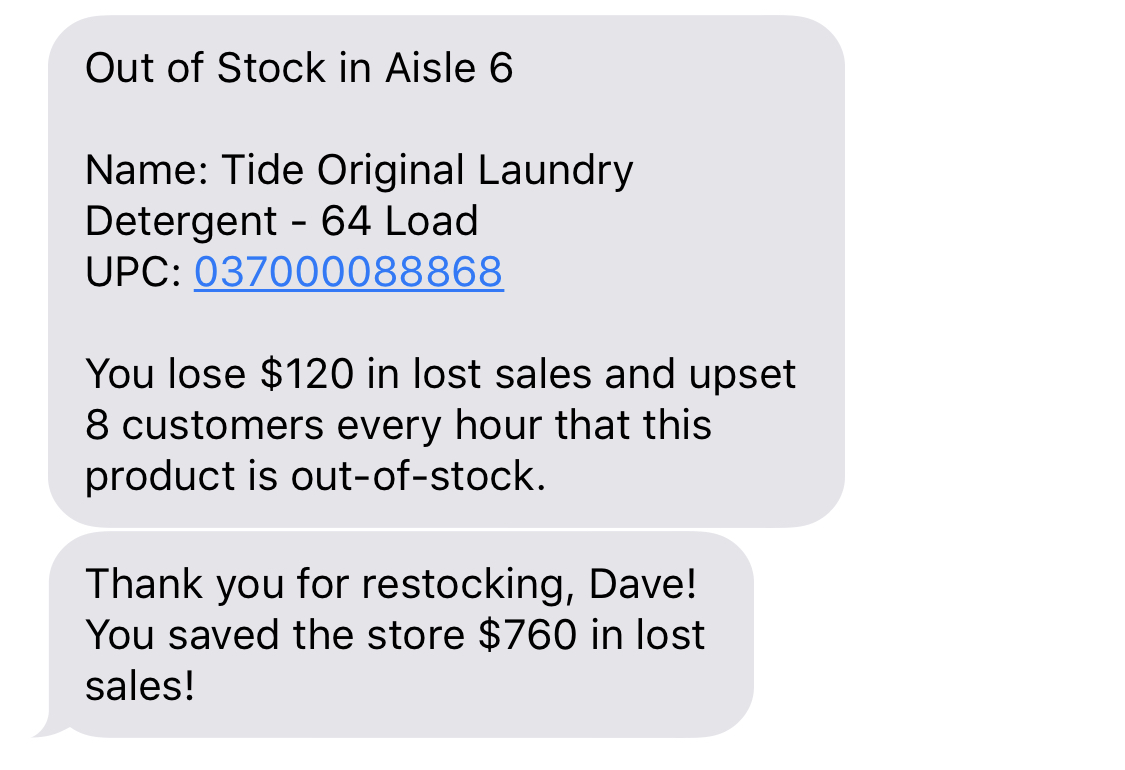

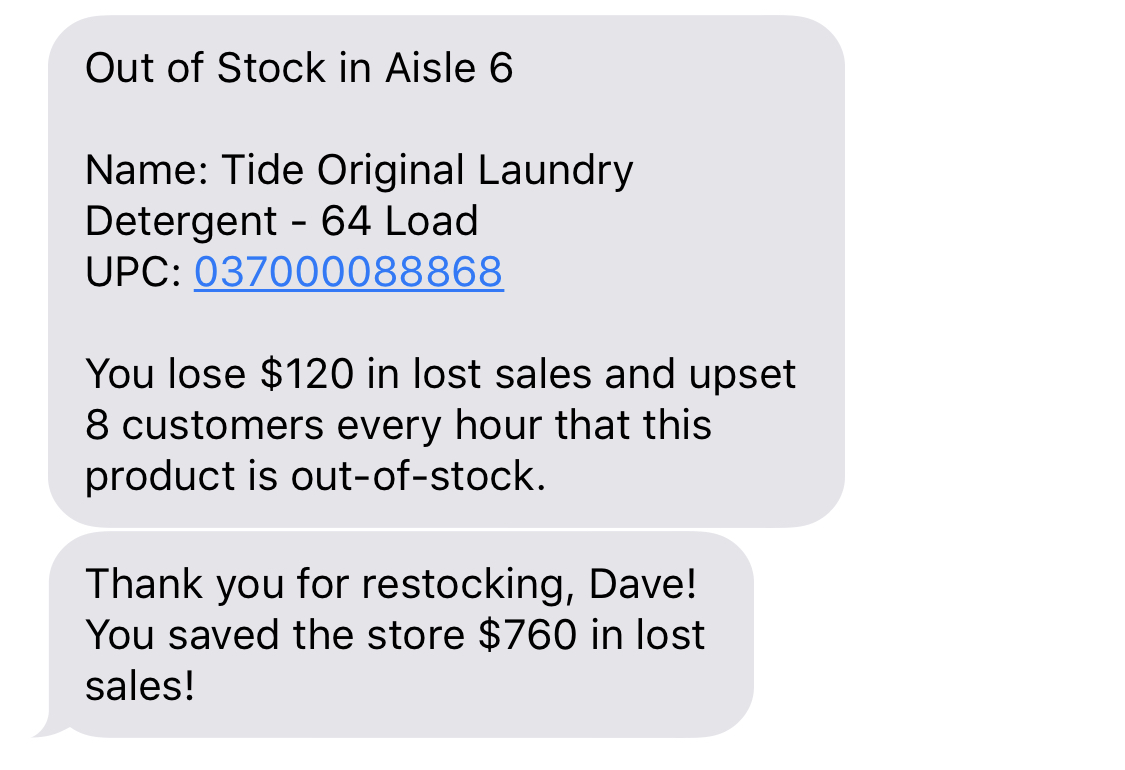

2. Instant Alerts on your "never be outs"

Each out of stock has Lost Sales per Hour (LSH) and Frustrated Shoppers per Hour (FSH). Your goal as a store manager should be making the most of the labor hours you have in order to minimize both. If your staff is currently working a slow mover (i.e. Mint Jelly where LSH=$.1 and FSH=0.1), and a fast mover goes out (i.e. Tide where LSH=$128 and FSH=10), your staff should drop what they are doing immediately, and go recoup those $128 in Lost Sales every hour that product is out.

Our Stocker Action Tools enable exactly that. The tablet rank sorts your outs as they occur by LSH and FSH to recoup the most lost sales possible per labor hour to make the most customers happy.

2. Instant Alerts on your "never be outs"

Each out of stock has Lost Sales per Hour (LSH) and Frustrated Shoppers per Hour (FSH). Your goal as a store manager should be making the most of the labor hours you have in order to minimize both. If your staff is currently working a slow mover (i.e. Mint Jelly where LSH=$.1 and FSH=0.1), and a fast mover goes out (i.e. Tide where LSH=$128 and FSH=10), your staff should drop what they are doing immediately, and go recoup those $128 in Lost Sales every hour that product is out.

Our Stocker Action Tools enable exactly that. The tablet rank sorts your outs as they occur by LSH and FSH to recoup the most lost sales possible per labor hour to make the most customers happy.

3. On-Shelf Availability Analytics per hour

You depend on Average Basket Size, Number of Transactions, and Shrink. We offer a fourth pillar, Out of Stock Hours. Since we know the duration of each out of stock, we can sum that up to give you a high level metric of On-Shelf Availability to track from store to store.

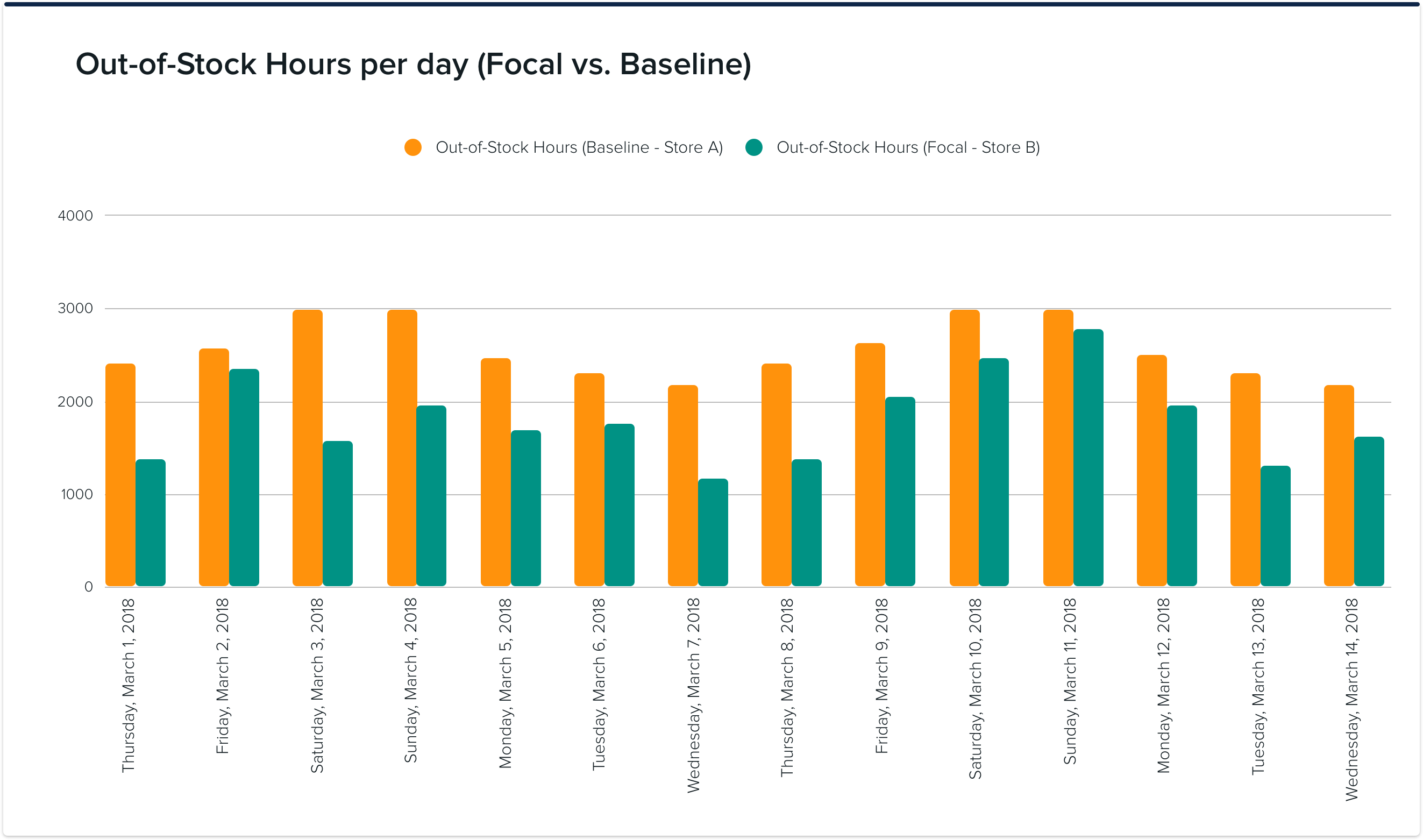

The graphic shows an A/B test of 2 stores to measure the change in average pick velocity picking with Focal Systems tools and baseline. We see very clearly that Focal Systems enables changes in your Standard Operating Procedure (SOP) that will cause 30% reduction in your Out of Stock Hours per store with the same or less labor.

4. Up to 40% of stockers' labor hours become re-deployable

Focal Systems frees up labor in two important ways. First, your staff will no longer need to scan holes in the shelf, Focal has you covered! Second, and more impactfully, by increasing the pick velocity of your stockers by as much as 2x, you need fewer labor hours to get the same amount of work done. This can free as much as 40 labor hours a day to work on other areas of the store.

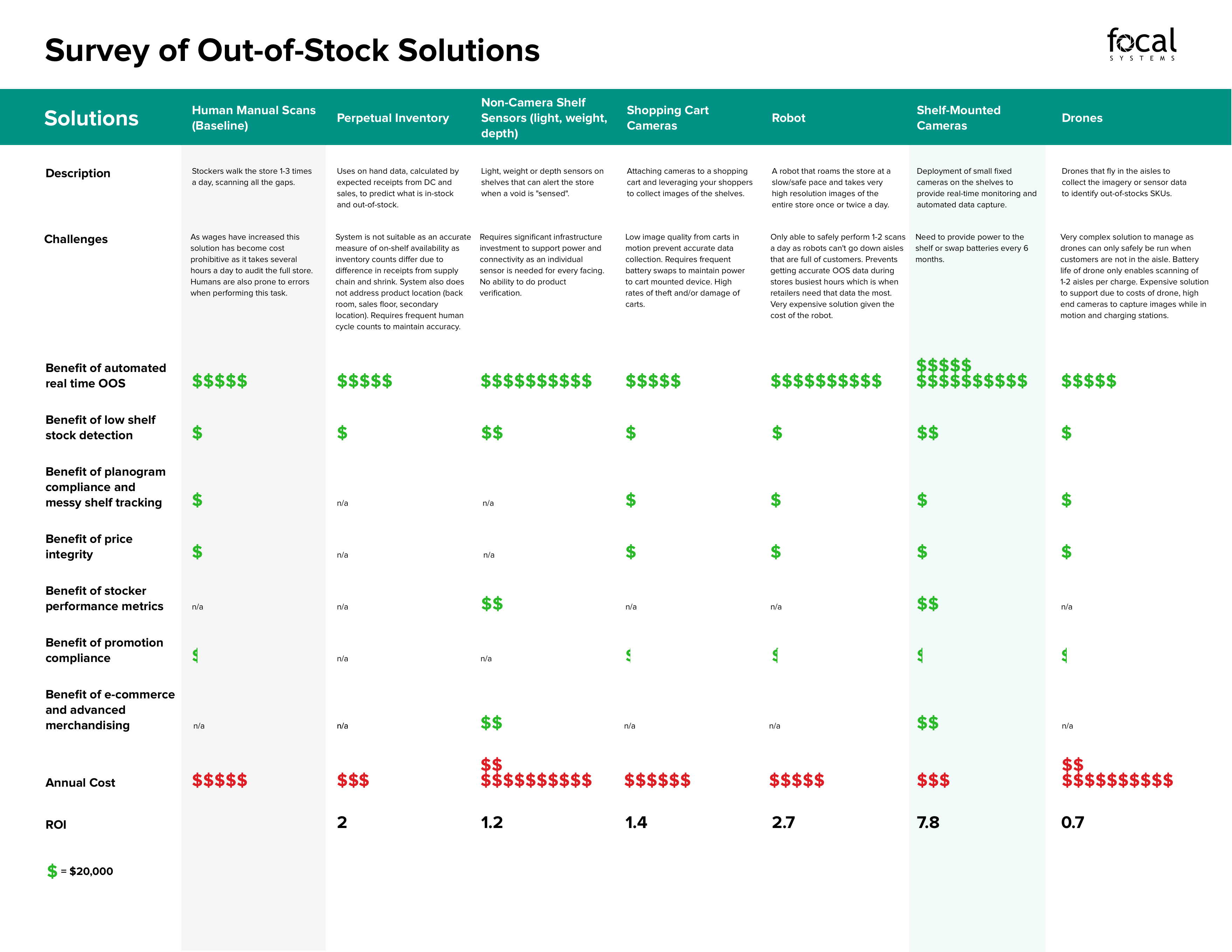

A Comparison of Out-of-Stock Solutions

See below a chart comparing different out-of-stock solutions, their value proposition, challenges, benefits and costs to see how Focal's Shelf-Mounted Cameras stack up against the competition. Click the chart or the "View the Chart in Full Resolution" button below it to see a larger version, or click the "Download the Chart as a PDF" button to download a PDF version of the chart.